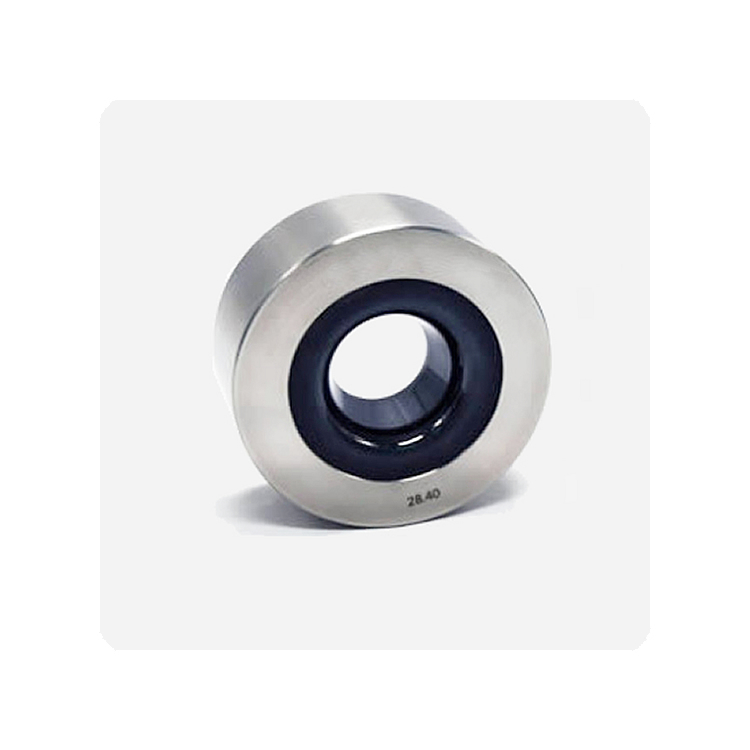

Nano diamond coating mould:a new mould is obtained by chemical vapor deposition (CVD) on the inner hole surface of the die with cemented carbide (WC Co) as the substrate. The diamond coating is precisely ground and polished to obtain a new mold.The product has the toughness of cemented carbide mold,the hardness and wear resistance of natural diamond,and the inner hole is bright and the friction coefficient is low Long service life.Mold inner diameter production range0.5mm-50mm.

Process and technology:

Process and technology:

Targeted pretreatment process:to make the coating and the substrate closely combined

Micro diamond coating:excellent wear resistance

Surface nano diamond coating:excellent surface finish and low friction coefficient

Optimization of pass design by computer simulation

mm |

inches |

ND |

SSCD |

PCD |

TC |

0.012-0.049 |

0.0005-0.0019 |

● |

● |

||

0.050-0.099 |

0.0019-0.0039 |

● |

● |

||

0.100-0.599 |

0.0039-0.0236 |

● |

● |

● |

● |

0.600-2.099 |

0.0236-0.0826 |

● |

● |

● |

|

2.1-15.9 |

0.0827-0.6260 |

● |

● |

||

16.0-35.0 |

0.6260-1.3780 |

● |

Diameter(inch) |

Diameter(mm) |

Tolerance(mm) |

Roundness(mm) |

≤0.00157 |

≤0.040 |

0.0003 |

0.0002 |

0.00158-0.00393 |

0.041-0.099 |

0.0005 |

0.0003 |

0.00394-0.01968 |

0.100-0.499 |

0.001 |

0.0005 |

0.01969-0.03936 |

0.500-0.999 |

0.0015 |

0.0008 |

0.03937-0.05905 |

1.000-1.499 |

0.002 |

0.001 |

0.05906-0.08661 |

1.500-2.199 |

0.003 |

0.0015 |

0.08662-0.12992 |

2.200-3.299 |

0.004 |

0.002 |

0.12993-0.18110 |

3.300-4.599 |

0.005 |

0.0025 |

0.18111-0.22834 |

4.600-5.799 |

0.006 |

0.003 |

0.22835-0.29921 |

5.800-7.599 |

0.007 |

0.0035 |

0.18111-0.41338 |

4.600-10.499 |

0.008 |

0.004 |

The advantages of nano diamond coated wire drawing dies are as follows:

1. Long service life:the service life of copper aluminum wire,low carbon steel wire,medium carbon steel wire,cable stranded wire,welding wire and die is 20-30 times more than that of cemented carbide mold,and that of cable stranded wire is more than 50 times that of cemented carbide.

2. The size control precision is high,the wire size is stable,and the size consistency can be maintained for a long time.

3. The inner hole of the mould is bright,the self lubrication is good,the surface friction coefficient is small,the surface finish of the wire rod is high,the material is not sticky,the quality of the finished wire is good,and the loss of equipment and equipment can be reduced at the same time.

4. The length of wire is 1%-2% longer than that of traditional mold.

5. Repair free mode,maintenance free,reduce the number of downtime detection,mold change,greatly improve production efficiency,unit time production significantly increased,saving a lot of labor costs.

6. It is suitable for drawing process without pickling,environmental protection and energy saving.

inches |

mm |

ADDMA |

IW |

Maximum Diameter |

0.0039-0.0157 |

0.100-0.400 |

D6 |

IWD3210 |

0.4 |

0.0079-0.0315 |

0.200-0.800 |

D12 |

IWD3215 |

0.8 |

0.0079-0.0394 |

0.200-1.000 |

D12 |

IWD4215 |

1.0 |

0.0197-0.0591 |

0.500-1.500 |

D15 |

IWD5225 |

1.5 |

0.0197-0.0591 |

0.500-1.500 |

D15 |

IWD4223 |

1.5 |

0.0315-0.0787 |

0.800-2.000 |

D18 |

IWD5235 |

2.0 |

0.0315-0.0787 |

0.800-2.000 |

D18 |

IWD4229 |

2.0 |

0.0472-0.1181 |

1.200-3.100 |

D21 |

IWD7240 |

3.1 |

0.0472-0.1181 |

1.200-3.100 |

D21 |

IWD6838 |

3.1 |

0.0591-0.1732 |

1.500-4.400 |

D24 |

IWD9553 |

4.4 |

0.0591-0.1732 |

2.000-4.400 |

D24 |

IWD6853 |

4.4 |

0.1299-0.2126 |

3.300-5.400 |

D27 |

IWD1285 |

5.4 |

0.1299-0.2183 |

3.300-5.800 |

D27 |

IWD12987 |

5.8 |

0.2008-0.2992 |

5.100-7.600 |

D30 |

IWD12912 |

7.6 |

0.3150-0.4331 |

8.000-11.000 |

D33 |

IWD15215 |

11.0 |

0.3150-0.4409 |

8.000-11.200 |

D30 |

IWD18213 |

11.2 |

0.3150-0.4724 |

8.000-12.000 |

D33 |

IWD18215 |

12.0 |

0.3150-0.4921 |

8.000-12.500 |

D33 |

IWD18217 |

12.5 |

0.3150-0.5000 |

8.000-12.700 |

D36 |

IWD18218 |

12.7 |

Application fields:

Copper wire,aluminum wire,wire and cable,stainless steel wire,medium and low carbon steel wire,stainless steel wire,low carbon steel wire,copper pipe,aluminum pipe,stainless steel pipe,etc.